How 'saving on freight' can cost you dearly

Certainty is the key to a successful supply chain. But with Logistics Managers under increasing pressure to cut their transport and logistics costs, it’s tempting to choose a supplier on price alone. But this choice is dangerous. It can compromise performance, and actually increase overall cost.

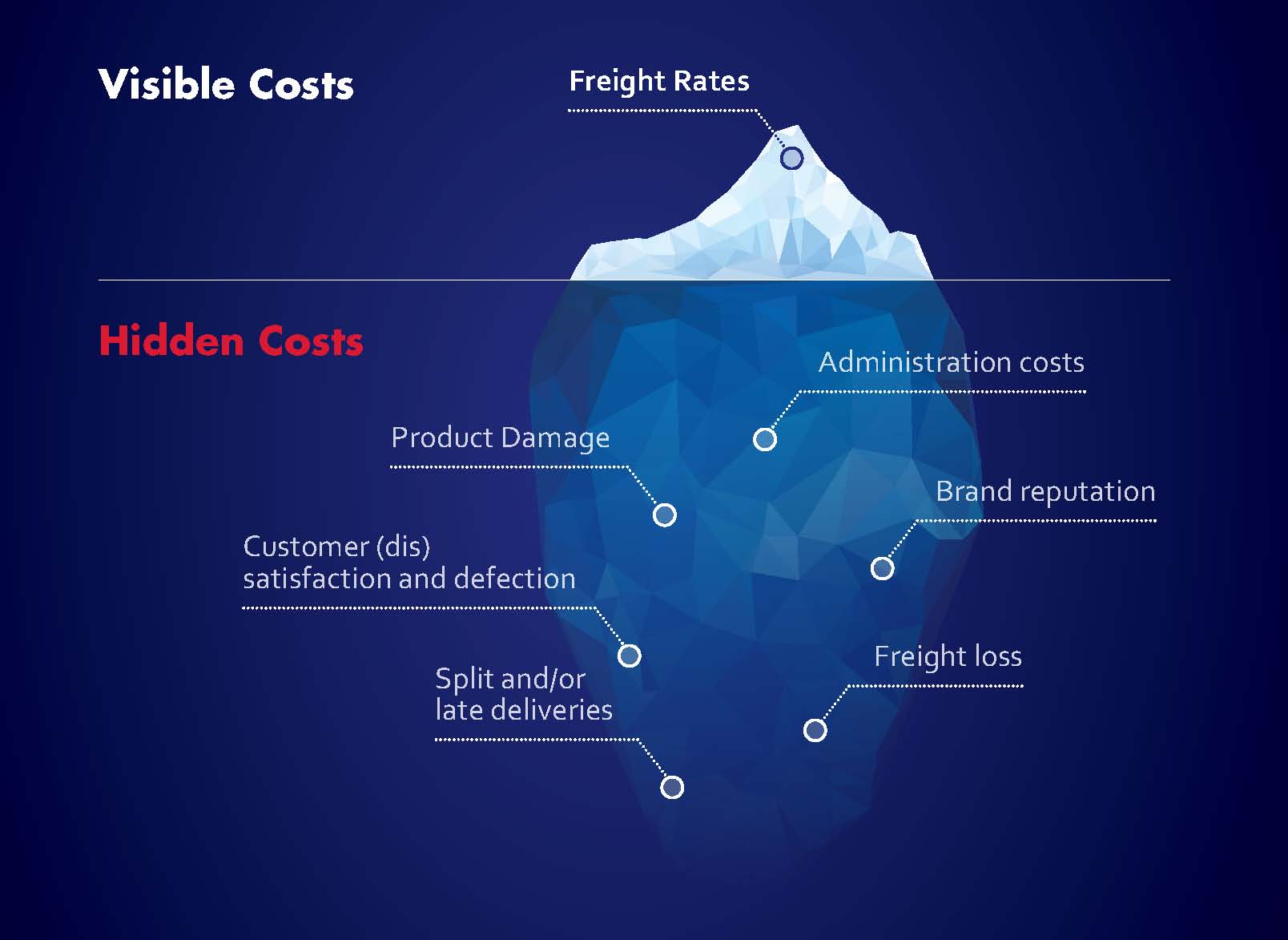

Beware the Hidden Costs

When assessing your supply chain, make sure you look at the total cost of running your business’ operations. These include the hidden costs of freight distribution. They may not be obvious during price negotiations, but they can do real harm to your overall profit.

1. Product Damage: When you’re running a transport and warehouse operation, some damage to your product is inevitable. But carriers with specialist freight handling techniques and technology can keep damage rates to a bare minimum. Some are willing to work with you to find other ways to minimise damage. And always ask whether they back their performance with the offer of a transit warranty.

Does your carrier provide warranties when damage happens? What’s their claims policy? What do these warranties cost you in additional charges?

2. Freight loss: Lost or stolen freight can hamper your profits and compromise response rates. Businesses dealing with high-value products are at particular risk of losing goods during the transport process.

Does your carrier have policies and procedures to protect your goods, from pickup through to final delivery?

3. Split or late deliveries: Delivery in full and on time (DIFOT) is a critical measure of delivery performance. You’ll see at a glance how often your customers get the goods they want when they want them, and their satisfaction levels.

DIFOT becomes crucial in the face of stringent delivery deadlines, lost sales, and the penalties retailers often impose for late orders.

Make sure you ask any potential carrier how regularly they measure DIFOT, and whether they’re willing to share this information with you.

4. Customer dissatisfaction and defection: Poor carrier performance can cost you customers. And remember, dissatisfied customers are ten times more likely to share a bad experience than a positive one.

5. Brand reputation: Missed delivery deadlines harm your brand’s reputation. Customers expect your business to be reliable, delivering within the promised time and cost.

This is especially vital when seasonality is a factor. Failure to deliver during key times (such as during the festive season), can seriously compromise a brand.

6. Administration Costs: Carrier failure can mean you and your customers have to chase deliveries, often wasting time on automated phone systems. A quality carrier helps you avoid these annoying delays by getting the job done right the first time. Meanwhile, you have the peace of mind to get on with building your business.

Tips for Choosing a Transport and Logistics Partner

When making this important decision, make sure you get the full picture. Remember, there are extra costs associated with a low-quality carrier, and be wary of administration fees and surcharges.

Make sure you ask about hidden costs, and what kind of warranties and service level agreements they’re willing to offer.

Download the Hidden Costs Flyer

Learn more about the hidden costs of freight distribution and how they can have a very real and negative impact on your overall profitability.